Global Machining, Plating & Anodizing Facilities

Serving Manufacturers in North America, Europe & Asia

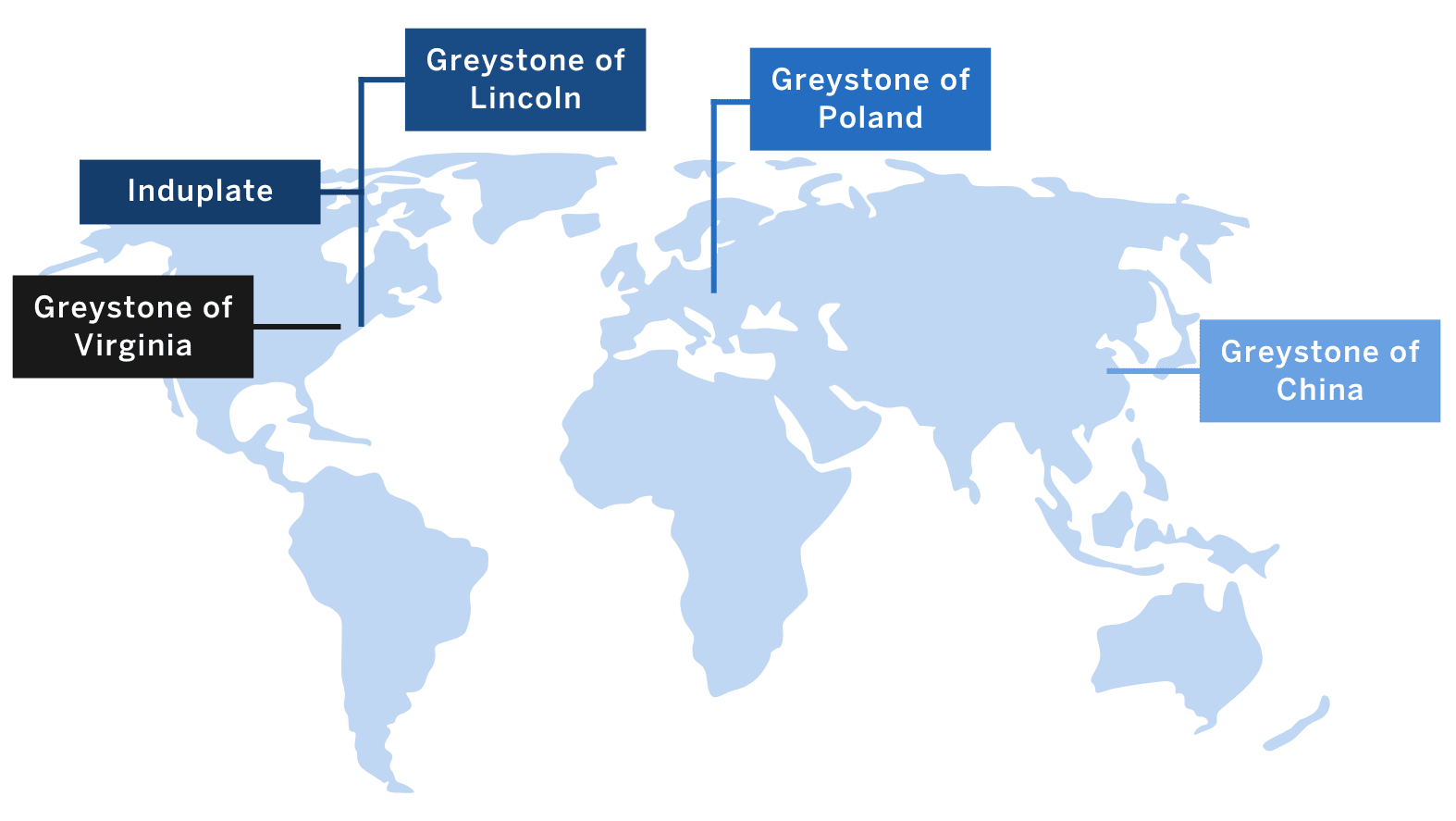

Manufacturers across the world rely on Greystone for its best-in-class machining, plating and anodizing services. To meet the needs of our global clientele, Greystone operates facilities in North America, Europe and Asia.

Our oldest plant, Induplate, opened in North Providence, Rhode Island, in 1932 to serve the industrial plating needs of manufacturers of hard-to-plate parts. Decades later, Greystone acquired a high-volume machining plant (now Greystone of Lincoln) a few miles north of Induplate. In the early 90s, Greystone founded a second plating facility in Toano, Virginia. All three of our U.S. plants are located near ports and major highways to ensure efficient service and delivery.

Outside of the U.S., Greystone has facilities in China that provide plating services. We also have a plating plant in Stalowa Wola, Poland, which opened in 2020.

The Benefits of Greystone’s Global Footprint

Global manufacturers across a range of industries – including automotive, aerospace, defense, medical and semiconductor – rely on Greystone to machine and finish their safety-critical parts.

Our over nine decades of manufacturing experience is augmented by our skilled workforce and robust, in-house tooling and custom automation capabilities. This allows Greystone to deliver precision tuned parts with 4 PPM, superior electroplating services, and precision type II and type III hardcoat anodizing for a range of aluminum alloys.

Regardless of the facility where components are machined or finished, manufacturers can rely on Greystone to quickly deliver high-quality parts cost-effectively. The primary benefits of our global footprint include:

- Consistency: The same proven processes, chemistry, technology and controls are used at each of our facilities

- Risk mitigation: The breadth of services offered at each facility makes contingency planning easy in case needs change or issues arise

- Scalability: Greystone’s presence on three continents makes international expansion easy – and eliminates concerns about inconsistencies in quality, service or cost

- Flexibility: Parts can be produced or finished offshore and shipped throughout the world

Services & Industries Served

Hover over the map and click for more information about each Greystone facility.

Map

Greystone of Virginia

A world-class ISO 9001 and IATF 16949 certified high-volume plating facility that specializes in products with tight tolerances

Services include: Precision Plating System, thin dense chrome (TDC), hard chrome, anodizing (types II and III), electropolishing and passivation

Primary industries served: Automotive, industrial, defense, medical

Induplate

A precision-plating facility that specializes in wear- and corrosion-resistant coatings for high-volume applications; ISO 9001, IATF 16949, NADCAP Chemical Processing, NADCAP AQS, ISO 13485 and FAA Repair certified

Services include: SteriChrome, hard chrome, electropolishing, passivation, manganese phosphate, copper, nickel sulfamate, electroless nickel and zinc nickel

Primary industries served: Automotive, aerospace, defense, medical, semiconductor

Greystone of Lincoln

A 75,000 square foot and IATF 16949 certified facility that houses over 90 CNC and Hydromat rotary transfer, multi-spindle and single-spindle machines

Services include: Machining and secondary operations, including deburring, grinding and staking

Primary industries served: Automotive, industrial, defense

Greystone of Poland

A state-of-the-art, IATF 16949 certified facility that specializes in high-quality plating using Greystone’s proprietary Precision Plating System (PPS)

Services include: Precision Plating System, hard chrome, thin dense chrome (TDC)

Primary industries served: Automotive, defense

Greystone of China

IATF 16949 certified facilities that deliver superior plating services to the Asian market

Services include: Hard chrome, thin dense chrome (TDC), electroless nickel, zinc nickel, anodizing

Primary industries served: Automotive, industrial